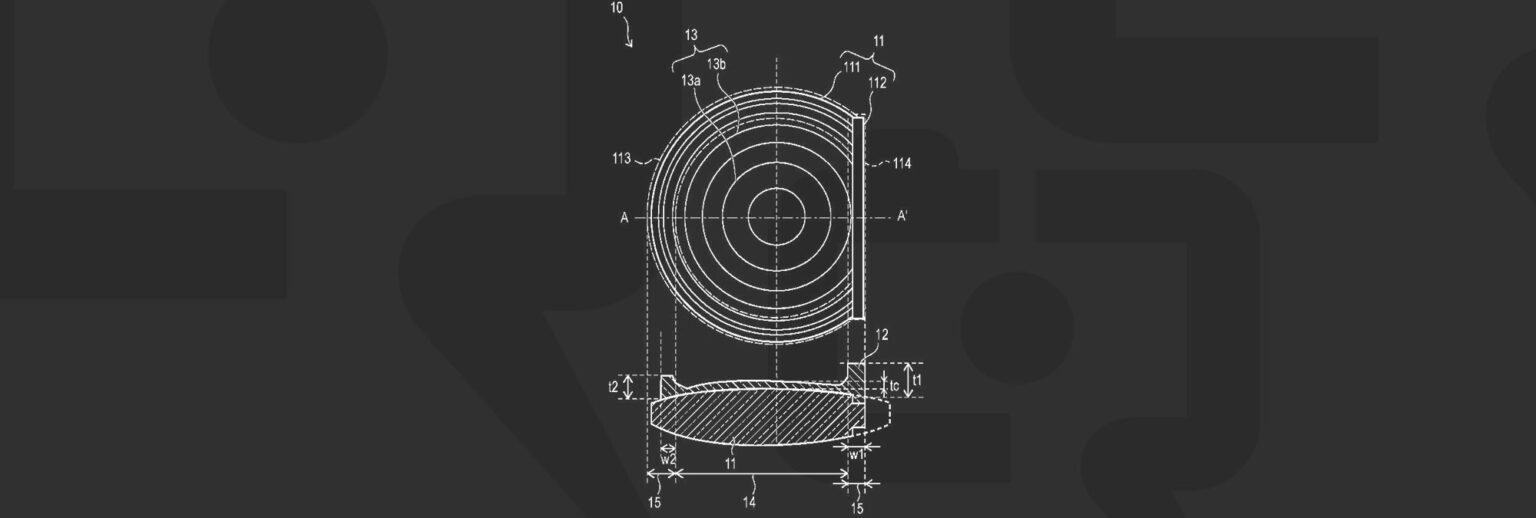

In this patent application (2024-135951) Canon is discussing how to improve the manufacturing of a diffractive optical element of a curious nature.

Canon hopes to improve the method of manufacturing the element including preventing cracks from forming during the curing stage of creating the element, which can be especially difficult given this shape the element is not fully uniform.

At first, I thought this was a special use case element because it shows a portion of the element cut away from a cure circular form as you would normally see on an element, however, Canon specifically mentioned that the element can used in camera lenses.

The diffractive optical element 10 according to the first embodiment can be used for the lenses 203, 205, for example. Here, the lens 205 is supported by an inner tube 204, and is movably supported relative to the outer tube of the lens barrel 201 for focusing and zooming.

In the below diagram, 205 is the diffractive optic element that is described in this patent application.

I would assume for a camera lens only the 13a portion of the diffractive optical element would be used by the lens, and 13b, in this case, would not be used.

Canon really doesn’t explain why they would create an element with a portion snipped away like this but there must be a reason why they would do it. I could see it for the other embodiment which is for an HMD (head-mounted display), but not really in the case for lenses.

In all, I’m wondering if the machine translation on this patent is particularly poor – but it’s good to see diffractive optics make it back into Canon’s R&D as I haven’t seen much research over the past year about that particular niche of optics.

Does anyone have any thoughts on why Canon would do an element shaped in this manner? I’m at a loss, but I’m sure there’s clever reason.

Japan Patent Application 2024-135951

|

When you purchase through links on our site, we may earn an affiliate commission. Here's how it works. |

They are already doing something like this with that 28mm pancake...